A Five-Year-Old Explains Process Mapping and Control Charts

What Can We Learn from Scott and Michael?

THE AIM for this entry is to share with you an inspiring video I came across on LinkedIn earlier today of two pint-sized process improvement impresarios explaining their class project on process mapping and control charting.

Young Michael first takes us through understanding their process flow-map of their start-of-day routine from entering the classroom to sitting at their desks, while Scott deftly steps in to help amplify some points before pivoting to their “Time to Tidy Up” control chart. And like all good process improvement experts, he of course wrote a book to share his knowledge with others.

While watching the video, besides being impressed with their command of the subject matter, I couldn’t help but wonder what has happened to this dynamic duo since the video was made (2012 or earlier?): did they hang on to this knowledge, or was it lost to time over their academic career? Do they still remember this presentation? Did they later rediscover their lost knowledge to teach to others? Questions without answers, of course: many unknown and unknowables.

What Would Make it Better?

Of course, Scott and Michael had some help from a “master” to help guide their learning. In this respect, as good as their presentation is, it could be even better if their teacher suggested a connection between the process flow map and the control chart, one way or the other.

For example, Start of Day Process Flow Map accompanied by a Time to Start Class Process Behaviour Chart, or a Tidy Up Process Flow Map accompanied by a Time to Tidy Up Process Behaviour Chart.

Following this, I don’t think it would be too much of a stretch to have introduced the concept of improvements and how to spot them on the chart — or not, as the case may be.

Patrick’s School Bus Arrivals Chart

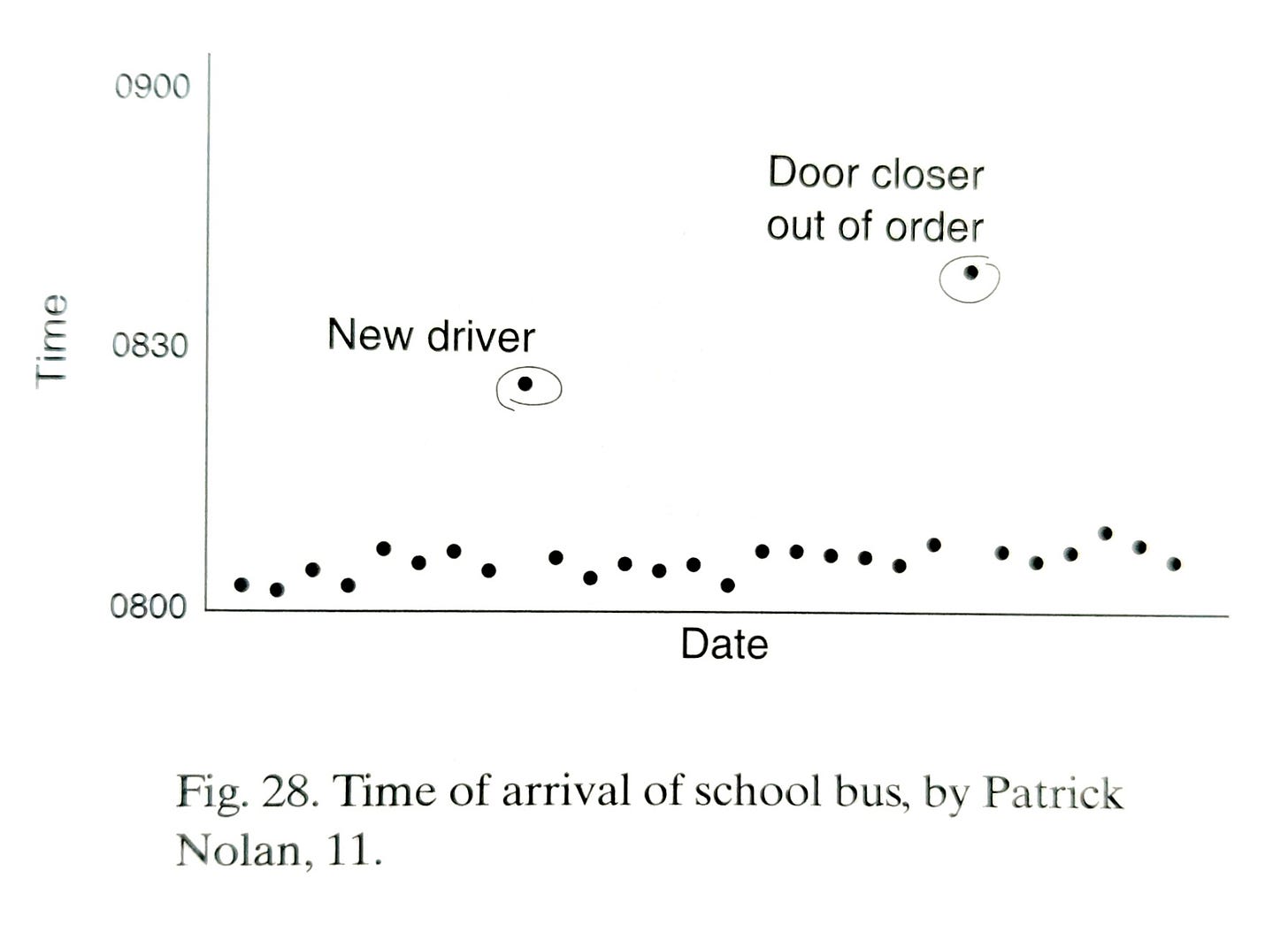

In The New Economics, Dr. Deming relates an anecdotal story brought to him by Dr. Thomas W. Nolan about his son Patrick, then 11, who had created a chart describing his school bus arrival times, which Deming found so impressive that he had to include it in his book:

So said Dr. Deming:

Patrick had kept a record day by day of the time of arrival of the bus that came to carry him off to school, and plotted the points. He recognized by eyeball special causes of delay on two days.

Think of what a good start in life Patrick had, understanding common causes and special causes of variation at age 11. He had recognized without calculation special causes of delay on two days, and had shown his explanation for the delays.

I similarly wonder what happened to Patrick, who is now old enough to have sent kids of his own off to university. Did he retain any of this knowledge to share with them?

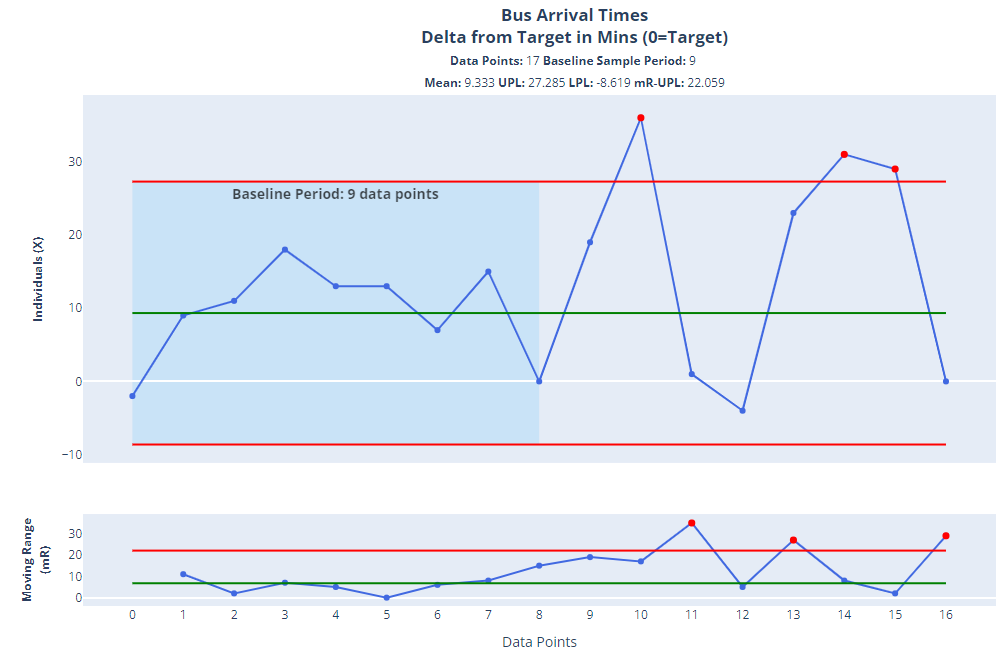

Similar to Patrick, I began tracking my daughter’s school bus arrival times at the end of the day in mid-October. Her bus is supposed to drop her off at 1630h, but is frequently late owing to traffic, construction, and route changes to accommodate “one-off” student drop-offs. In contrast to Patrick’s chart, I decided to track how many minutes early or late the bus was on a PBC, which you can see in the demo version of PBC Analyzer PRO:

As you can see, it’s been a rare day when the bus was on-time, and the driver would readily agree as he combats “special causes” daily that interrupt his schedule. The special causes shown are attributable to changes in his route that the bus company makes, sometimes within hours of when he has to begin his pick-ups from various schools. This introduces all sorts of variation as he contends with irregular traffic patterns and obstructions that cause delays. Sometimes my daughter is waiting for up to forty minutes after school has ended before she’s picked up!

It bothers the driver that he can’t meet his commitments, and damages his ability to take pride in his job, which he ordinarily has. Were he and his management to track data like this, there might be a different understanding of how to manage unexpected route changes to minimize disruptions, or to better set expectations for drop-off times.

Reflection Questions

Consider Scott and Michael’s presentation: how could something similar be inspired in your organization? What workshops or seminars could be started to encourage similar learning and sharing of knowledge between peers? Are there Scotts and Michaels in your system (perhaps you?) waiting to be discovered? What processes could be profiled to kick off learning this way? Let me know your thoughts below.